Structural Steel

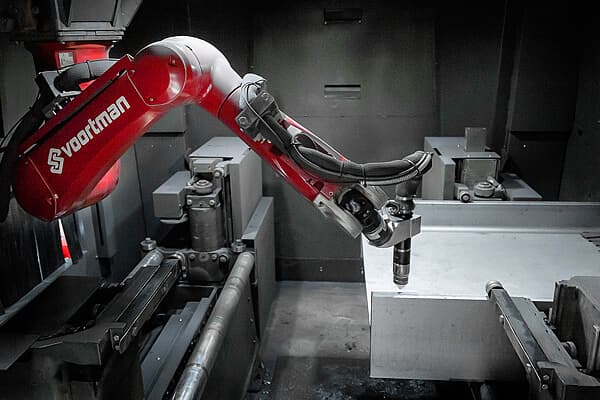

The top-ofthe-range coping robot and profiling robot make 3D coping easy. These Robotic Coping & Profiling beams are reliable, as well as being able to cut saddles, chamlers or slots.

METEOR-1200 has the ability to cut down on your labor, whether you are drilling or performing on-site assembly. METEOR-1200 has the ability to drill beams and angles, flat sheets, and other suitable geometry. With the state of art control system, you can also mill slots and pockets.